This is your complete guide to adding water to a battery.

Watering batteries is a major part of what we do at Foxtron.

So we wanted to pass on our expert knowledge to you.

In this article, you’ll learn:

- Why lead-acid batteries need water

- When to add water to a battery

- Safety tips for watering batteries

- How to add water to a battery, step-by-step

- And lots more!

Let’s dive in!

To answer this question, we first need to understand how lead-acid batteries work.

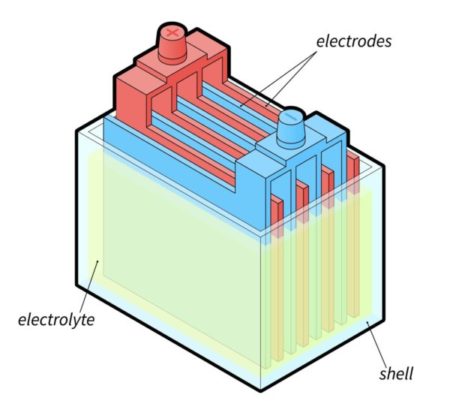

Lead-acid batteries generate electricity through an electrochemical reaction between lead plates and electrolytes.

The electrolytes are a mixture of water and sulphuric acid.

And the water protects the battery’s active material while it generates power.

Without water, the active material will oxidize and the battery will lose power.

And that’s why lead-acid batteries need water.

Why Do Lead-Acid Batteries Lose Water?

As the battery is charged, electricity flows through the electrolyte.

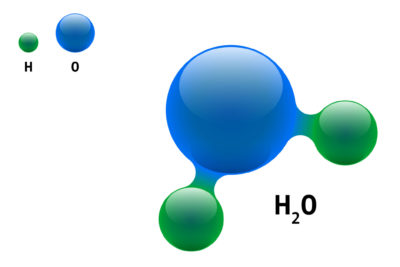

When this happens, water in the electrolyte is split into its original elements - hydrogen and oxygen.

This process is called gassing.

And it’s through this gassing process that battery water is lost.

But depending on what kind of acid is in a battery, it may not be necessary to water it.

For example, low maintenance batteries like gel and AGM batteries do not need regular water top-ups.

That’s because these batteries are sealed.

And being sealed allows the atoms to reform, preventing water loss.

On the other hand, vented batteries allow the gases to escape, which leads to water loss.

Thus, vented batteries must be regularly checked for water loss and topped up as needed.

Why Do You Need to Maintain Your Forklift Battery Water Levels?

If the water level drops too low, the battery’s lead plates can oxidize.

And this can lead to battery low on water symptoms like:

- Reduced battery power

- Not charging fully

- Reduced battery lifespan

If not solved, the damage may become permanent, rendering the battery useless.

Adding water to a lead-acid battery can be risky.

Because of the battery’s chemicals, there’s the risk of both injury and damage.

These chemicals present various dangers such as:

Acid splashing

Corrosion

Skin burns

Inhaling toxic gases like hydrogen

Therefore, you need to follow certain safety tips when watering batteries.

Wear Proper Personal Protection Equipment

Before you start handling your battery, you’ll need to get the proper personal protection equipment (PPE).

OSHA requires that those handling batteries wear:

- Face shield

- Apron

- Rubber gloves

PPEs will reduce the potential skin contact with the electrolyte and protect you from the dangers of forklift batteries.

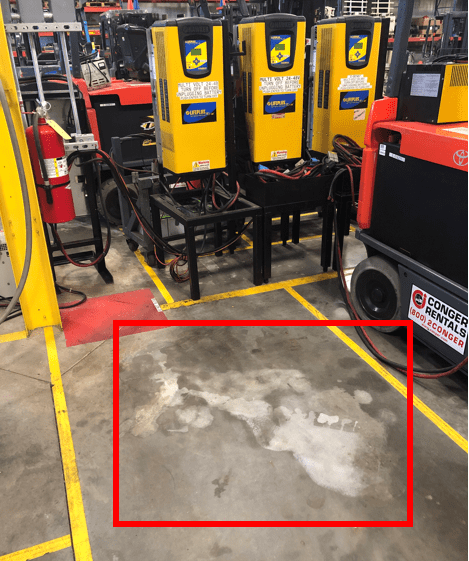

Only Water in Designated Areas

Make sure you only water batteries in an appropriate area, consisting of:

- A stable and level surface

- Adequate ventilation

- Absence of spark- or flame-producing items

Although the electrolyte isn’t flammable, there’s a possibility of sparks or flames.

That’s due to possible residual hydrogen gas inside the battery cell after the charging process.

Additionally, if there are bystanders in the watering area, make them aware of the watering process (and situation).

That way they can take caution as well.

There is no predetermined time to add water to the forklift battery.

But in general, you should add water every five to ten charging cycles when the battery electrolyte level is low.

When to add water depends on:

- How often the battery is charged

- How much water the cell can hold

- The age and condition of the battery

So, often the best way to determine the best watering schedule is simply by experience.

How to Check the Battery’s Water Level

You can check the battery fluid level either manually or by using a battery water level indicator.

Here’s how to check battery water level manually:

-

Remove the cell cap or vent cap on every battery cell

-

Check if the electrolyte is covering the top of the protective splash plate. If so, it doesn’t need water

-

If the electrolyte level is below the splash plate and some plates are exposed, the battery needs watering

Using a battery water level indicator is the simplest way to check water levels.

Simply check the indicator to see if it’s flashing red.

If it is, then you know you’ll need to add water.

If it’s flashing green, there’s enough water in the battery.

Should You Add Water to a Battery Before or After Charging?

Only add water after charging (after a full charge) to allow for expansion.

Also, you should only add water after the battery has cooled.

This is when the battery’s water level is at its highest after expansion.

And it’s important to allow for expansion since it can help prevent boilovers.

How Much Water Should You Add to a Battery?

You should add water until the electrolyte level is 1/8″ above the plates or about ¾” below the top of the cell.

What to Do If You Add Too Much Water to the Battery

It’s very important not to overfill your batteries.

When adding water to a lead-acid battery, you need to leave enough space for the fluids (water and sulfuric acid) to expand when the battery is charging or in use.

Otherwise, you can cause the batteries to bubble over, overflow, and spill the electrolyte solution.

And that can result in injury or damage if the solution comes into contact with the skin and other items.

In addition, adding too much water may dilute the electrolyte.

And that can dull the battery’s power, resulting in reduced performance.

If you overfill the battery, you may need to empty some of the electrolytes.

Because this can be dangerous, we recommend contacting a battery professional for help.

Why Use Distilled Water in Batteries?

It is recommended to add distilled water to a battery.

That’s because distilled water is purified and free from additional minerals you would find in tap water.

Tap water is not recommended because it can upset the chemical balance.

How?

Tap water contains minerals.

And these minerals react with the battery’s chemicals, converting them into non-rechargeable ions.

These ions can not take part in any electric storage.

Moreover, tap water will react with the electrolyte and minimize battery performance as well as increase sediment.

And this can harm battery materials.

Where to Buy Distilled Water for Batteries?

Pure distilled water costs a little more because distillation removes impurities.

Where you get the distilled water depends on the amount you’ll need to use.

For larger operations with many batteries, it’s best to buy distilled water from an industrial supplier.

However, if you only need a little bit of distilled water and are on a budget, you can make it yourself.

Doing so is fairly simple and only involves a demineralization device or a few pots and pans.

Do Not Add Acid to the Battery!

Adding acid to a battery makes it deteriorate faster.

Why?

During normal operation, batteries only consume water – not acid.

And if you add acid, you’ll disrupt the electrolyte’s balance.

Another reason not to add acid is that it’s simply dangerous.

So when you observe the electrolyte to be lower than needed, only fill the battery with water.

But if the electrolyte is spilled and you need to add acid, contact a battery professional for this service.

Adding water to lead-acid battery cells is a simple process if conducted carefully.

Overall, there are two ways to do it:

- Adding water manually (directly) into individual cells using a battery filler gun or nozzle

- Adding water automatically using a battery watering system

Adding Water Using a Manual Filling Gun

You will first need to purchase the battery watering gun separately from the forklift battery.

Then, here’s how to fill a battery with water directly through a watering gun or nozzle:

-

Ensure the battery is fully charged and cooled

-

Put on your PPE

-

Open the cell vent caps for every cell

-

Connect the battery watering gun to a standard water hose or water deionizer

-

Adjust the battery water gun correctly for the particular battery

-

Fill with enough water to cover the top of the plates. Put the tip of the gun into the battery cell until it contacts the splash plate

-

Activate the water flow on your device. You can do this by squeezing the handle**

-

Repeat the process until all cells are watered. Keep adjusting the depth indicator until each battery cell is watered to the same level

-

Once done, close and replace or retighten all battery cell caps

** Note: The design of these devices allows them to shut off water flow under backpressure. This means the flow will shut off automatically when the water level reaches the tip of the gun or nozzle. This is your indicator to move onto the next cell.

Adding Water Using a Battery Watering System

Watering systems automate the watering process to speed it up and minimize hazards in the battery watering process.

There are a variety of battery watering system brands, but they all function similarly.

The process of battery watering systems looks like this:

-

Remove the dust cap from your equipped watering system

-

Attach the equipped watering system to the water source. Or connect the input hose to the filling machine

-

Turn on the filling machine and activate the water flow

-

Monitor the flow indicator on your watering system. It will shut off when each cell has been filled with the appropriate amount of water

-

You can also wait until the machine stops and disconnect the watering hose

-

Once done, close and replace or retighten all battery cell caps**

-

When you’re done watering, clean up any spills around the battery cells

** Note: Although watering systems are designed to reach and fill every cell, we recommend double-checking each cell afterward. This will help ensure all cells are at an adequate and equal level above the plates.

Conclusion

There you have it: The complete guide to adding water to a battery.

Now, we’d like to hear from you.

What did you learn about battery watering from this article?

Do you have further questions?

Please let us know in the comments section!