In this post, we answer 27 of your most frequently asked forklift battery and charger questions.

To make it easier, we split the questions up into 4 main categories:

- Battery basics

- Charging basics

- Battery maintenance

- Battery repairs and replacements

Let's dive in!

Table of Contents

1. What Are The Different Forklift Battery Types?

Most forklifts use one of two main types of batteries:

- Lead-acid

- Lithium-ion

Let’s briefly cover the basics of both.

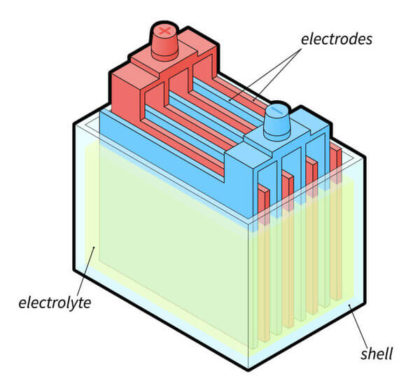

Lead-Acid Batteries

Also called “wet” or “wet cell” batteries, lead-acid forklift batteries are the most common type.

They generate electricity through an electrochemical reaction between lead plates and the fluid electrolyte (a mixture of sulfuric acid and water).

They are widely available and less expensive than lithium-ion.

However, they require more maintenance, take longer to charge, and have a shorter lifespan.

Also, they vent out flammable hydrogen gas during charging, making them a greater safety concern.

Lithium-Ion Batteries

Lithium-ion batteries are a newer battery technology that’s gaining popularity.

They use lithium as the electrolyte for electricity generation.

The benefits lithium-ion batteries offer include:

Faster charge rate

No leaks because they're sealed

Virtually no maintenance requirements

Last twice as long as lead-acid batteries

However, lithium-ion batteries are more expensive than lead-acid.

2. What Are The Different Forklift Battery Voltages?

Common forklift battery voltages include:

12 volts. Used in small and light lift equipment such as powered pallet jacks

24 volts. Used in smaller lift equipment such as end-riders, center-riders, and walkie stackers

36 volts. Designed for mid-size lift equipment such as narrow aisle forklifts, 3-wheelers, and some 4-wheelers

48 volts. Used in larger lift equipment such as 4-wheel counterbalanced forklifts

72 volts. Used in larger counterbalanced forklifts with greater capacities

80 volts. Used in large material handling equipment such as pneumatic counterbalanced forklifts

Among these voltages, 24, 36, and 48-volt batteries are the most common.

3. How Much Sulfuric Acid Is In A Forklift Battery?

Forklift battery acid is composed of 30% to 50% sulfuric acid, and the remaining part of the electrolyte is water.

That said, the amount of sulfuric acid in the battery varies depending on the voltage and charge state.

The higher the voltage and state of charge, the higher the concentration of sulfuric acid.

4. How Many Hours Does A Forklift Battery Last?

A lead-acid forklift battery is designed to last a full 8-hour shift when fully charged.

But this can vary depending on the usage and age.

For instance, a battery used for lifting heavy loads, long-distance travel, or rough terrain can wear out sooner.

5. How Long Do Forklift Batteries Last?

A lead-acid battery can last 1,500 charge cycles or 3 to 5 years.

And a lithium-ion battery can last 3,000 cycles or 10 years.

Overall, battery lifespan depends on many factors, including:

Usage

Charging method and habits

Maintenance practices

Storage

Brand quality

6. What Are The Types Of Battery Charging Methods?

There are three methods of battery charging:

- Conventional

- Opportunity

- Fast

Let’s cover each one in a bit more detail.

Conventional Charging

This is the most common method.

Using a low current of about 16 to 18 amps per 100 amp-hours, this method can charge a battery in 8 to 10 hours to a 100% state of charge (SOC).

The battery is then left to cool down for 6 to 8 hours before the next use.

It's the best charging method for a battery's longevity, on account of the lower current involved.

Opportunity Charging

This method uses a specialized charger and higher current (20 to 30 amps per 100 amp-hours) to charge batteries quickly, often in as little as 30 minutes.

That makes opportunity charging perfect during shift changes, lunches, break times, and other downtimes.

The battery is charged to an 80 to 85% state of charge to limit gas generation, then put back into service.

Opportunity charging is not ideal for maintaining maximum battery lifespan, because the higher current involved wears out the battery faster.

Fast Charging

This is similar to opportunity charging but uses a higher current rate of 30 to 60 amps per 100 amp-hours for 20 to 30 minutes.

Like opportunity charging, fast charging is extremely tough on batteries and likely to cause them to wear out much faster.

7. How Do You Choose An Electric Forklift Battery Charger?

If you already have a variety of forklift battery chargers, selecting the right one for your battery comes down to 2 main things:

- Matching the voltage. To find the charger voltage, check the charger’s nameplate. Then, compare it with the battery voltage, which is located on the battery’s nameplate, intercell connector, or model number

- Matching the amp-hours. A battery's amp-hours is the total amount of current it can produce within one hour. You’ll want to choose a charger that is within 10% of the battery’s amp-hours. The battery’s amp-hours can be found on the nameplate, intercell connector, or calculated from the model number. The charger’s amp hours can be found on its nameplate

For a more detailed explanation, check out this article.

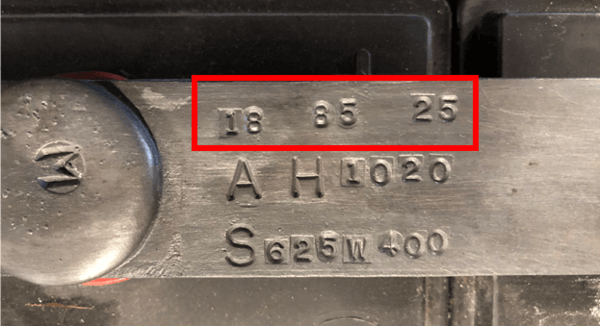

How To Calculate Battery Amp-Hours From the Model Number

If you can’t find the amp-hour rating of your forklift battery on its nameplate, you can calculate it from the model number.

You can find the model number on the side of the battery or the intercell connector:

Here’s how to do it, using a model 18-85-25 battery as an example:

Take the last number (25)

Subtract 1 (25 - 1 = 24)

Divide by 2 (24 ÷ 2 = 12)

Multiply by the middle number (12 x 85 = 1,020)

The product is the amp-hours of the battery (1,020 amp-hours)

How To Tell If The Amp Hours Are In Range

As we said above, your charger’s amp-hours should be within +/- 10% of the battery’s amp hours to avoid under or overcharging the battery.

Here’s how to perform the calculation to determine if the amp-hours are acceptable, using a 680 amp-hour battery as an example:

Multiply the battery's amp-hour rating by 1.1 to find the upper limit: 680 x 1.1 = 748 amp-hours

Multiply the battery's amp-hour rating by 0.9 to find the lower limit: 680 x 0.9 = 612 amp-hours

This means your charger amp-hours must be between 612 and 748 amp-hours.

8. How Many Amps Does It Take To Charge A Forklift Battery?

The amount of amp-hours needed to charge a forklift battery varies depending on the charging method:

Conventional chargers charge at 16-18 amps per 100 amp-hours. This takes about 8 hours to charge fully

Opportunity chargers charge at 25-30 amps per 100 amp-hours. This takes just over 30 minutes to charge the battery to 80%

Fast chargers charge at 40-60 amps per 100 amp-hours. This takes 20-30 minutes to charge to a usable level

9. How Often Should You Charge A Forklift Battery?

Charge the battery when the charge level is between 20 and 30%.

You should avoid charging the battery when it's above 40% because you'll use up limited cycles, causing it to wear out faster.

And you should avoid charging the battery when it’s under 30% because waiting that long causes the battery to heat up during use, leading to shorter service life.

10. How Long Does It Take To Charge A Forklift Battery?

Lead-acid batteries using a conventional charger can charge to 100% in 8 hours.

It's recommended to use the 8-8-8 rule: 8 hours of charging, 8 hours of cooling, and 8 hours of operation.

But in general, how long it takes to charge a forklift battery depends on several factors, including the:

State of charge. A higher state of charge will take less time than a lower state of charge

Capacity. High-capacity batteries take longer to charge compared to low-capacity batteries

Type of charger in output. While conventional charging to 100% takes about 8 hours, opportunity and fast charging can get the battery to a usable state of charge in as little as 20 to 30 minutes

11. Can You Charge A Forklift Overnight?

Yes, you can.

But you can also use fast and opportunity chargers to charge during downtimes, like breaks, lunches, or shift changes.

12. Can You Overcharge A Forklift Battery?

Yes, it's possible to overcharge a forklift battery.

Especially if you use a charger with a higher amp-hour output than your battery is designed to handle.

This is why it’s important to select a charger that’s within 10% of your battery’s amp-hour rating.

Otherwise, you can damage the battery, void the warranty, and reduce its useful life.

13. What Are The OSHA Requirements For Battery Charging Stations?

OSHA requires the following for a forklift battery charging area:

Separate the charging area. Forklift charging stations should be away from other facilities and areas

Charge batteries in a well-ventilated room. Because of toxic and explosive hydrogen fumes during charging, charging areas must have ventilation to prevent these gasses from accumulating

Include an eyewash station. Eyewash requirements for battery charging stations include having clean water for emergency eye cleaning in case the battery acid splashes into someone’s eyes

Hang appropriate signage. This includes “No Smoking” or “No Open Flames” signs to alert users and operators

Have fire extinguishers present. In case of a fire, it’s important to have extinguishers readily available

Have proper personal protective equipment (PPE). Proper PPE for battery charging areas includes aprons, face shields, goggles, and rubber gloves

Have an acid-neutralizing kit. In case of boil-overs or accidental spills of electrolyte, you should have a kit to neutralize the acid

14. How Do You Charge A Forklift Battery?

What step should you take before charging a forklift battery?

When charging a battery on a forklift start by:

- Parking the lift truck at the battery charging station, setting the parking brake, switching off the ignition, and remove the key

- Raising the lift truck's hood (for heat dispersion and ventilation purposes)

- Before connecting the battery, check and make sure the charger is turned off

- Check to make sure that the voltages of the battery and charger match

- Check and make sure the amp-hours of the battery and charger match

- Check the forklift charging cables and connectors for wear or damage and replace before charging

- Disconnect the battery from the truck

- Connect the charger to the battery (NOT to the truck connector!)

- The charger should start automatically. Stop if you:

- Smell smoke

- See sparks

- The battery gets very hot

- The electrolyte leaks out

- If none of the above occurs, continue charging and wait until the battery is 100% charged

- If the charger has a "Stop" button, press it to terminate the charge. If the charger is automatic, it will stop charging when the battery is at 100%

- Disconnect the cables and connectors from the charger

- Once the battery has cooled down, check the water level and add water if needed

- Reconnect the battery to the truck

15. How Do You Revive A Dead Forklift Battery?

Is your forklift battery too low to charge?

If the battery is completely dead - so much so that the charger can't detect it when plugged in - you may need to use a manual "trickle" charger.

This charger will supply a constant current to the battery to get it charged to a level that the regular charger can detect.

16. Can You Jumpstart A Forklift Battery With A Car?

You can jumpstart an internal combustion forklift battery with a car battery since they're similar.

But you can't jump an electric forklift battery with a car battery.

You'll have to use a manual trickle charger, as stated above.

17. What's All Involved With Electric Forklift Battery Maintenance?

Forklift battery maintenance procedures involve:

Inspections. Inspect the battery case, cables, connectors, and vent caps. They should be present, clean, and undamaged. Replace them or have a professional repair them if needed

Equalizing. Equalize the battery weekly to help prevent sulfation and keep the battery cells at an equal level

Watering. Check battery fluid levels and add distilled water if need be. Always maintain the correct battery water level to prevent cell plate deterioration

Washing. Wash the battery regularly — at least every month — using warm water and acid-neutralizing degreaser and dispose of the water according to regulations

18. Why Is It Important To Water Forklift Batteries?

Lead-acid batteries generate electricity through an electrochemical reaction between lead plates and an electrolyte solution.

When charging, this process is reversed, and in doing so, forklift battery water evaporates.

And when it evaporates enough, it exposes the lead plates, which leads to their deterioration.

Adding water to the battery covers the plates back up and helps preserve their integrity.

19. What Happens If A Forklift Battery Runs Out Of Water?

If the water level goes too low, the lead plates will be uncovered and exposed to oxygen and hydrogen.

This exposure results in an exothermic reaction between these gasses and the battery's terminals, emitting large amounts of heat.

The heat can further evaporate the water, and the plates may degrade, reducing the battery’s lifespan.

20. What Happens If You Add Too Much Water To A Forklift Battery?

If you add too much water to a forklift battery, you risk a boil-over during charging.

When this happens, the battery will lose some of the caustic electrolytes.

And spilled battery acid is corrosive, leading to damaged infrastructure and injury and burns.

21. When Should You Add Water To A Forklift Battery?

How heavily the battery is used dictates how often you water it.

So there's no exact answer.

But you should check the battery water levels after each charge and add water when needed.

And importantly, you should only add water to a forklift battery after charging or equalizing once it's cooled down.

At this time, the battery's water level is highest and a boil-over is less likely.

22. What PPE Is Required For Watering Forklift Batteries?

Your PPE should include an apron, gloves, and face mask or goggles.

Also, remove metal items like jewelry and watches to prevent electrocuting and/or burning yourself on the battery terminals.

23. What Are The Forklift Battery Watering Procedures?

Follow these steps while manually (directly) adding water to a battery:

- Find a battery filler gun or nozzle

- Let the battery fully charge and cool down first

- Wear the appropriate PPE

- Open every cell's vent caps

- Connect the watering or filler gun to a standard water deionizer or hose

- Adjust the nozzle collar so that it only fills the cell with enough water to be just above the plates

- Fill each cell

- Water all cells using the same procedure

- Close all battery cell caps and tighten them

Also, consider keeping a battery watering record.

This helps if a warranty claim is made because manufacturers often require proof that the battery has been watered to consider the claim.

24. What Are Battery Watering Systems For Forklifts?

A battery watering system consists of a series of tubes and nozzles that are inserted into each forklift cell.

To use it, you simply connect your water source to the system and turn on the water.

And once each cell is full, the water shuts off automatically.

The advantage of a battery watering system is that they automate the whole process, make it faster, and minimize hazards such as spillage.

25. How Much Does An Electric Forklift Battery Cost?

A good rule of thumb is that the cost of a new lead-acid forklift battery is approximately ⅓ of the forklift's total cost.

But the cost depends on the forklift model.

After all, larger forklifts require larger, more expensive batteries.

That said, here are a few examples of common lead-acid forklift battery costs by forklift model:

Walkie pallet jack: $1,200

Order picker: $3,300

Stand-up counterbalance: $4,300

3-wheeler: $4,800

Mid-size 4-wheeler: $6,200

Large 4-wheeler: $9,200

80-volt outdoor 4-wheeler: $7,600

Lithium-ion batteries are more expensive - about 2x as much as lead-acid.

26. How Do I Know If My Forklift Battery Is Bad?

The most common signs of a forklift battery that’s going bad include:

Loss of power

Lower run times

Longer charge times

Increased heating

You may also see evidence of excessive sulfation, which is often one of the main causes of the above problems.

Not sure what sulfation is?

It’s the build-up of lead sulfate crystals on the surface of the active material of the battery's lead plates.

These crystals often disperse during recharging or equalization.

But they stick when the battery is irregularly charged or equalized.

As a result of sulfation, the battery loses active material, which causes it to lose power over time.

Sometimes sulfation can be reversed with charging and equalizing, but other times it cannot.

In the latter case, you’ll need to replace the battery.

27. Should You Recondition or Replace Your Forklift Battery?

Whether to recondition or replace your forklift battery depends on its condition and your budget.

Reconditioning

Why recondition your battery?

For 2 main reasons:

It’s less expensive than replacing it

It’s better for the environment as fewer batteries are used

But reconditioning is not appropriate all the time.

For example, it may not be possible if too many cells have gone bad.

Furthermore, reconditioned batteries may not last as long and have a reduced power capacity.

It’s for this reason that reconditioning works best for light-use equipment and single-shift operations where the lift truck isn't used all the time.

And to be sure, reconditioning requires professional forklift batteries services.

This is because it involves skilled, and potentially dangerous work, such as forklift battery cell replacements.

How Long Does Battery Reconditioning Take?

Reconditioning can take your equipment offline for 1 to 2 business days.

You may also experience longer lead times if particular cells aren't available.

Replacing

Wondering “when should I replace my forklift battery?”

If you’re getting less than 4 hours of run-time, which indicates less than 80% remaining capacity, you may want to consider a forklift battery replacement.

Conclusion

There you have it: Your 27 frequently-asked forklift battery and charger questions answered.

Now, we'd like to turn it to you.

Did you learn anything that surprised you?

Are there other questions you want us to answer?

Please share with us in the comments section!

Have a customer with a floor cleaner fitted with 18 cell 7PZS 630 Gell battery, needs one cell replacement due to positive terminal failure. New Gell cell 6-8 weeks delivery. Can an equivelent lead acid cell be fitted? would the Gell charger cope with this.

Thanks

Mark

You may want to check with the gel battery manufacturer to confirm this is doable before attempting. But as long as the lead-acid cell is a 1-to-1 match to the gel cells, you should be able to use it. Gel batteries do require special chargers to limit voltage spikes, but lead-acid is more forgiving. So charging shouldn’t be a problem either.

That said, using a lead-acid cell can have downsides that could affect your decision. One, they’re liable to sulfate, which can make a mess. Two, they require regular maintenance including topping off with water. Three, they can vent dangerous hydrogen gasses unlike sealed batteries. I hope that helps!

I have a question about charging a lead acid battery with an ultra charge charger. My question is after charging my forklift battery with the ultra charge battery charger the charger read out stated that the battery was charged at 100% however after disconnecting the battery from the charger and then connecting the battery to the forklift. The battery’s current charge display still displayed 2 bars short of 100%. Could you explain to me why and what this could mean please.

Hi Ty,

Great question! The most common reason this happens is actually because of an error on the truck-side. To confirm, you could check the battery voltage manually using a voltmeter. If the battery is fully charged, then you know it’s not the charger’s readout causing the discrepancy. What the problem could be is the battery discharge indicator (BDI) or other electronic dash components located in the lift truck. See if it doesn’t reset itself after a few power cycles (i.e. on/off of the key switch). If you’re still experiencing the problem, I’d encourage you to contact your nearest service center for more advanced troubleshooting. Thanks and good luck!

Comments are closed.