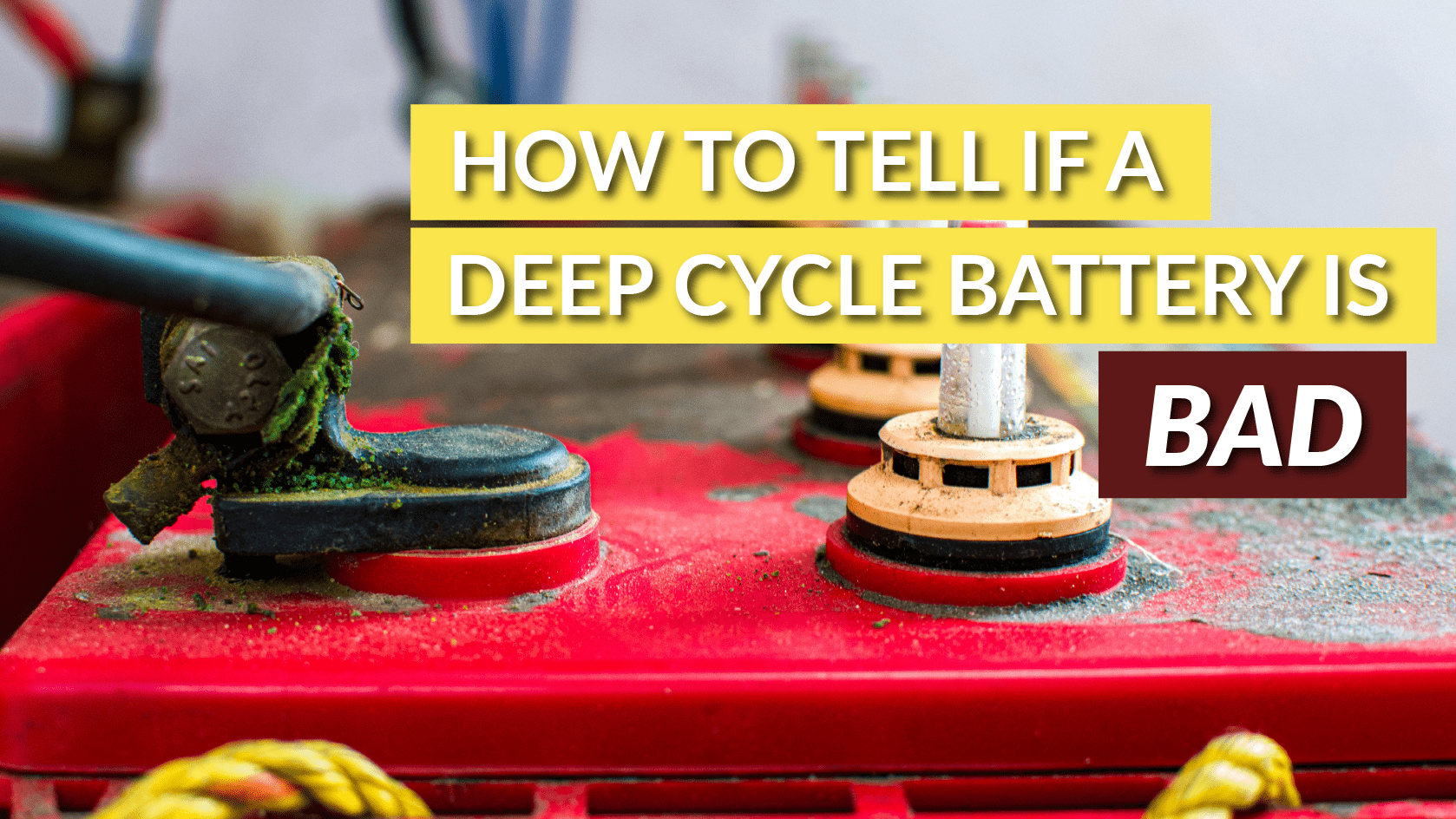

This guide explains how to tell if a deep cycle battery is bad.

In it, you’ll learn:

- Why deep cycle batteries go bad

- When a deep cycle battery is considered “bad”

- How to test a bad deep cycle battery

- Tips for maintaining deep cycle batteries

- And much more!

Let’s get started!

When your deep cycle battery won’t fully charge or charge at all, the battery is experiencing failure.

Other symptoms of a “bad” deep cycle battery include when the battery:

Doesn’t hold a charge

Shows sluggish performance

Experiences shorter run times

But why do deep cycle batteries go bad?

They’ve Reached Their Age Limit

For starters, deep cycle batteries have an age limit.

Forklift batteries, for example, usually last about 1,500 cycles.

And after this point, they begin to fail.

They’re Too Sulfated

Sometimes, deep cycle batteries can fail even sooner than their expected lifespan.

Most often, this happens because of a chemical issue called “sulfation.”

What is sulfation?

Sulfation is the formation and build-up of lead sulfate crystals on the surface of the battery’s lead plates.

Often, sulfation occurs when the battery is deprived of a full charge.

When this happens, sulfation reduces the surface area of chemical reactions.

And this causes the loss of plate capacity, which reduces battery performance.

Overall, most premature deep cycle battery failures are due to sulfation.

They Have Dead Cells

Dead battery cells occur when the plates shed active material.

This is due to expansion and contraction in the battery during its normal charge and discharge cycles.

When the material sheds, it causes a loss of plate capacity.

And this results in a buildup of sediment in the bottom of the cell, called sludge (or “mud”).

When this happens, these cells can short out the plates and end up “killing” the entire battery.

They Have a Short Circuit

Not just bad cells, but loose terminals can also cause short circuits.

Shorts produce a lot of heat as the current is instantly released.

If the battery short circuits, there will be evidence of burning or melting on the battery.

They Have Damage to the Case, Terminals, or Cell Connectors

Damage to batteries can result from several things.

This includes:

Corrosion

Mishandling

Excessive vibration

Loss of water

Negative grid shrinkage

Overcharging

For example, you can see evidence of excessive corrosion on this forklift battery:

If bad enough, this damage will cause the battery to go bad.

A deep cycle battery is considered “dead” when the active material in the plates can no longer sustain a discharge current.

Of course, you can’t tell this just by looking at it.

So, how do you tell when a battery is dead?

You’ll be able to tell if the battery drains quickly or cannot charge at all.

But you can also know when a battery is dead by checking its voltage.

Typically, the voltage of a fully charged, 12-volt deep cycle battery is between 12.8V and 13V.

But a dead battery’s voltage is below 10 volts.

It is vital to detect battery problems at an early stage to resolve them.

You can only tell if a battery is bad or good if you inspect the battery regularly and test it if need be.

The three methods to test a deep cycle battery are:

Visual inspection

Checking the voltage

Performing a load test

To get started, you’ll need the right deep cycle battery test equipment.

This includes a voltmeter, hydrometer, and battery charger.

Once you have the right equipment, follow the steps below to test your battery:

Safety First!

Before handling lead-acid batteries, you need to take precautions against hazards like corrosion, flammable and explosive hydrogen gas, electric shocks, and burns.

That means you should:

- Use proper personal protective equipment (PPE) including an apron, goggles, face shields, rubber gloves, and safety footwear

- Work in an open or well-ventilated area

- Remove metal jewelry, avoid smoking, and eliminate any other ignition sources

Step 1: Visual Inspection

Testing starts from the outside and moves to the inside.

So, here’s what to do during the visual inspection:

Look for Damage

Look for cracks or bulges in the case, broken terminals, excessive corrosion, broken cell connectors, and excessive leaks.

If found, remove the battery from service immediately.

Then, contact a battery professional to schedule repairs.

Note: AGM and gel batteries are designed not to leak, even if the case is damaged. But flooded lead-acid batteries will leak. Here’s the full Gel vs. Lead-acid battery comparison.

Look for Dirt and Debris

Check the top of the battery and the terminals for dirt and grime.

If found, clean them up.

If you don’t, they can cause the battery to self-discharge.

And this can greatly reduce battery life.

The next two visual inspections only apply to flooded lead-acid batteries because you cannot open sealed (AGM and gel) batteries.

Check That There’s Adequate Water in the Cells

Check the battery's electrolyte level and make sure it covers the battery plates.

If the electrolyte is low, top up with water.

Why is this necessary?

When in use, batteries only consume water - not sulfuric acid.

And if the electrolyte is low, it will self-discharge at a high rate.

This, in turn, will cause premature battery aging and possibly failure.

Check the Color of the Water Inside the Cell

The water shouldn’t be dirty or discolored.

If it is, there’s a problem with the cell.

And if one cell is compromised, the whole battery is compromised.

Check the Specific Gravity Readings

Specific gravity is the electrolyte’s weight compared to the weight of an equal volume of water.

Why is that important?

Because it tells you the electrolyte’s strength.

And a properly mixed electrolyte is key to the proper functioning of the battery.

The specific gravity in a fully charged battery cell should be between 1.280 and 1.300.

If the specific gravity is off (over 10 points below or above), you’ll need to adjust the electrolyte.

So, how do you check the specific gravity?

First, you’ll need a hydrometer.

Then, using the hydrometer, remove some of the electrolytes and add water to lower the gravity if it is high.

If the gravity is low, you’ll need to add acid.

But because adding acid can be a dangerous activity, we recommend you contact a qualified battery technician to do this.

You can learn more about specific gravity and how to measure it in our Forklift Battery Maintenance Guide.

Step 2: Check the Voltage

Checking battery voltage can help to give you a clue into the health of the battery.

The voltage after a full charge will reveal internal battery issues like:

Short circuits

Dead cells

Stratification

Sulfation

Before testing the voltage, you’ll want to complete a full charge.

IMPORTANT: Actual Voltages Aren’t as They’re Advertised

Each cell in a battery (just after a full charge) is 2.2 volts.

After resting for 12 to 24 hours, the voltage drops to 2.1 volts per cell.

So, a charged but rested 12-volt battery will actually be around 12.6 volts after charge.

And a 6-volt battery will read 6.4 volts.

It’s important to understand this, so you don’t get a false reading.

Then, you’ll need to remove the surface charge.

What Does Surface Charge Mean?

Surface charge is the extra voltage in lead-acid batteries that occurs because of the delay in converting lead sulfate to lead and lead dioxide after charging.

Why should you remove the surface charge?

A lead-acid battery with a surface charge has a higher voltage.

Thus, this can give a false voltage based on the battery’s state of charge (SoC) reading.

Now, surface charge is not a symptom of a battery defect.

It’s actually a reversible situation.

So, How Do You Remove Surface Charge?

One way is to briefly place an electrical load on the battery - such as turning on any lights connected to the battery.

This will remove about 1% of the battery’s capacity.

Alternatively, you can allow the battery to rest for a few hours after charge before taking a volt reading.

Measure the Voltage

Once you’ve removed the surface charge, you’ll want to read the voltage to determine the state of charge.

You can do this with a multimeter.

The multimeter indicates the voltage with a solid and a dashed line above the letter “V.”

For example, here’s how to test a 12-volt deep cycle battery with a multimeter:

-

Set the multimeter dial to 20. This will allow you to measure the battery between 0 and 20 volts accurately

-

Now, touch the meter’s red probe to the positive terminal and the black probe to the battery’s negative terminal. The battery’s terminals are marked “+” and “-”. And they’re usually color-coded with red for positive and black for negative

-

Notice that if you’re getting a reading with a minus in front (e.g., -12.6 instead of 12.6), it means you’ve placed the probes the wrong way around! Change them and read them again

Correlate the Voltage to the State of Charge

Once you have the voltage, you’ll want to correlate that with the battery’s state of charge.

The state of charge (in %) to voltage reading should be as indicated in this 12-volt deep cycle battery charge chart:

100%: 12.7 to 13.2 volts

75%: 12.4 volts

50%: 12.2 volts

25%: 12.0 volts

Discharged: 0 to 11.9 volts

This will tell you your battery’s health level.

For example, if your battery is:

0 volts - it indicates a short circuit

Below 10.5 volts - it indicates a dead cell(s)

Below 12.4 volts, but charger indicates it’s 100% - the battery is sulfated

What Should a 12-Volt Battery Read When Fully Charged?

As we’ve discussed, the battery’s ideal resting voltage should be no lower than 12.6V.

If it goes down to 12.2V, then it’s only 50% charged.

And if it’s below 12V, that means the battery is discharged.

Step 3: Perform a Load Test

Load testing batteries involves measuring the actual capacity of a battery under an electrical load.

This test essentially shows you how well your battery will perform under normal conditions.

Where Can You Load Test Batteries?

For consumer-use batteries (6-volt, 12-volt), you can buy and use a deep cycle battery load tester.

For larger industrial batteries (like forklift batteries), you’ll need an industrial load tester.

But these are prohibitively expensive.

So, you’ll need to contact a battery service center (like Foxtron) for this service.

How to Load Test a Deep Cycle Battery Using a Load Tester

This is the general process for conducting a load test:

-

Make sure to charge the battery 100% before you start

-

Measure and record the specific gravity of each cell (do not start the test unless specific gravity is below 1.280)

-

Measure and record the standing voltage for each cell

-

Connect the load tester and apply an electrical load to the battery

-

Every hour, for 6 hours, measure and record the voltage of each cell

-

The test is complete when either a cell’s voltage drops significantly or when no battery cell drops below 1.70 volts within 6 hours

How to Tell If a Battery Is Bad from a Load Test

Once the load test is complete, you can estimate the capacity of the battery as follows:

- 1st hour complete: 60%

- 2nd hour complete: 70%

- 3rd hour complete: 80%

- 4th hour complete: 90%

- 5th hour complete: 100%

If a battery cell’s voltage drops significantly during the test, that indicates that the cell is bad and should be replaced.

What Should You Do If Your Battery Failed the Load Test?

First, load test it again to confirm.

And if it still fails, it’s time to repair or replace the battery.

Can a Bad Battery Test Good?

Yes, this is possible.

Batteries with open cells can read fully charged in idle but may fail under a load test.

You need to conduct a load test and the other inspections we’ve mentioned here to check if the battery is good or bad.

Whether or not you can resurrect a dead deep cycle battery depends on the condition it’s in.

If the battery is damaged, you should discard it.

If the battery has suffered a dead cell, you can replace the cell.

But this can be very expensive.

So it may make more sense to simply replace the entire battery.

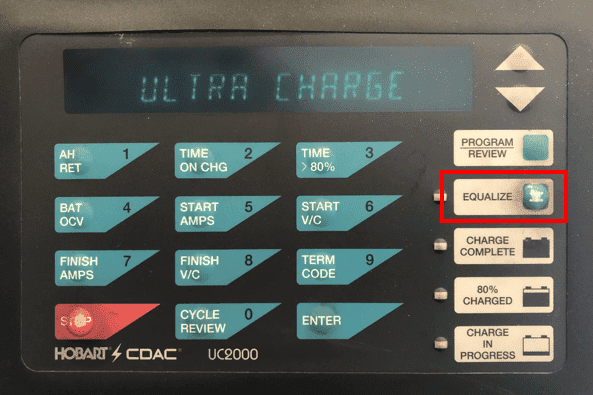

If the battery is dead due to sulfation, resurrecting it depends on whether the sulfation is permanent or reversible.

If it’s reversible sulfation, a typical equalization charge (overcharge) will help bring the battery back to life.

But if the battery is fully discharged, you can’t charge it with a smart charger (i.e., a charger that automatically detects charge state).

Why?

The charger won’t read enough of a voltage from the battery to start the charging process.

The solution?

Charge it using a non-smart, manual charger to deliver voltage without detecting the battery’s state of charge.

If you can’t do this, you can contact a professional technician or seek the services of a professional battery company like Foxtron.

Fortunately, many of the issues that cause deep cycle batteries to go bad are preventable.

It mostly comes down to keeping up on maintenance.

Here’s what you can do:

Conduct a capacity check for new batteries as part of acceptance to avoid buying low-performance batteries

Allow the battery to have a full charge of between 14 and 16 hours regularly

Charge in a well-ventilated area to prevent the accumulation of hydrogen gas

Inspect the battery regularly to note and repair any issues like damage and leakage

Water regularly to prevent sulfation and stratification. Don’t allow the electrolyte to drop below the plate-top levels. Exposed plates will sulfate and reduce the surface area for chemical reactions

When watering the battery, add only distilled or deionized water until it covers the exposed plates before charging

Never add acid to the electrolyte. This can raise the specific gravity and cause excessive corrosion. If acid needs to be added, contact a battery professional

Keep the battery charged, especially when not in use, to prevent self-discharge. Avoid storing the battery below 2.07 volts per cell or when the specific gravity level is below 1.190

Avoid deep discharges. Deeper discharges shorten the battery life. You can conduct a quick charge of 1 to 2 hours to prolong battery life

Keep the battery clean to prevent the accumulation of dirt that can interfere with the performance

Format a new deep cycle battery by applying gentle load for the first five charge cycles to gradually increase performance

Conclusion

There you have it: How to tell if a deep cycle battery is bad or not.

Now, we’d like to hear from you.

What did you learn?

Can you tell whether a deep cycle battery is bad or not?

Share with us in the comments section below!

How should a deep cycle gel battery used for a back up sump pump be maintained? Should it be allowed to have some discharge cycle or kept at full charge with a maintaining charger. I would expect limited use except for infrequent extended power outages.

Hi Neil,

Using a maintenance charger would be the best option, but it’s not absolutely required. Most gel batteries discharge only a small percentage of their total capacity each month, and can safely discharge to around 70-75% (check with the battery manufacturer to be sure). It’s a good idea to check on the battery at least every 3 to 6 months and give it a charge back to 100% if needed. I’ve included a couple links to articles that explain a bit more about deep cycle battery discharging and storage best practices:

– https://www.foxtronpowersolutions.com/deep-cycle-battery-winter-storage/

– https://www.foxtronpowersolutions.com/depth-of-discharge/

Thanks for reaching out and I hope this helps — cheers!

Hi, I have a deep cycle battery that is about 12 years old and hasn’t been charged in 5-10 years. It shows a few volts. I have tried both a marine battery charger with ‘manual’ position and a standard auto battery charger. Both peg the amp-meter on the charger then the breaker trips, resets after a few minutes, then the cycle repeats. I’ve left on for an hour or so and it takes a little charge but the voltage drifts down after removing the charger. Any hope for the battery or is it a lost cause? It’s an Interstate Deep-cycle Extreme 232 AH, I assume lead-acid type. Thanks for any help!

Hi Dave,

Thanks for reaching out. I think you might have a hard time resurrecting that battery if it hasn’t been charged in 5-10 years. At this point, it’s probably permanently sulfated and unlikely to come back. You’re probably better off dropping it off for a core charge and getting a newer battery. If you want to learn more about sulfation and its effects on batteries, check out our article here: What Is a Sulfated Battery? Tips for Prevention and Restoration

Hello. I bought a new battery 2 weeks ago. I had to top charge it before I could use it. It had an 80% charge then. 2 days later I took it out and it arched when I was going to the lake. The battery looked fine, only a few burn marks on the batter.. Boat bench took the worst of it. I’m worried I burnt a cell up. I put it on 2A white charging it. I took it off the charger when it was full and let the surface charge wear off. When I took it off, the voltmeter read 12.65 volts. After 6 hours it reads 12.56 volts. And after 24 it reads 12.53. 48 hrs 12.52 Did I damage it, or in this normal. For a new battery?

Hi Tony,

Based on the information you provided, it’s possible that the arcing was caused by damage to the battery, which may have resulted in contact between the positive and negative electrodes. You said that you see some burn marks on the battery case. It’s possible that the internal components may also have been damaged. You may want to have the battery inspected by a qualified professional to ensure that it is safe to use — especially given the potential safety concerns related to the arcing and shorting.

Regarding the voltage readings you provided, if they were taken without a load on the battery, they may not accurately reflect the battery’s actual state of charge or capacity. However, if the readings were taken with no load, the gradual decrease in voltage over time looks normal (though perhaps a little low) for a lead-acid battery that is not being used or recharged during that time.

To get a more accurate idea of the battery’s performance, it may be helpful to put a load on the battery. Then check the voltage at regular intervals to see how well it is performing. You may want to consult the manufacturer’s instructions or specifications to see what the expected voltage range is under a load. For example, here’s one such chart: https://electricscooterparts.com/battery-state-of-charge-chart-and-information.html

Again, if you have concerns about the battery’s condition or performance, it’s always a good idea to have it inspected by a qualified professional. They can see if there is any underlying damage that could pose a safety risk. Thank you for reaching out and good luck!

I purchased a 42-volt street legal golf cart 6 months ago and drove it 15 miles to home. It would work for 18 holes and more until recently. Now it dies after only a few miles. I checked the voltages. 6 of the 7 batteries read 6.1-volts however the 7th read 4.2-volts. The last time I charged the batteries, the charger got very warm and did not work right so I did not complete the charge. In addtion the detection Fault light turned on but subsequently went off, Will one bad cell cause the cart to die after a short usage. Was the Detection Fault light on due to the bad cell. If I replace only the 7th battery with the bad cell; will that solve the problem? Thanks for your help.

Hi Gregory,

I think you’ve identified exactly the problem and solution for your golf cart. One bad battery can indeed “spoil the bunch,” resulting in low performance. And it’s also likely the reason your fault indicator was going off. Try replacing the 4.2-volt battery with a new one — that should solve your problem. I also found this article https://www.usbattery.com/finding-the-weak-deep-cycle-battery-in-your-pack/ that you may find helpful. Good luck!

Hello,

first of all, thanks for the nice article about this!

I would like to know, how many times should i apply the “Repair/desulfating/ reconditioning option on my smart charger?

It runs for 24hr max then shut off. Do you think i would need couple cycle to really make sure its done well, or once and it should be good. Batteries are 8 years old. shows great voltage but after a little bit and with very low LED light drawing it dies. thanks for letting me know.

G

Hi G,

Thanks for your question! I’m not sure what model your smart charger is. But I did a little digging and found a manual for a Black & Decker model. (Here’s the link: https://m.media-amazon.com/images/I/A1mWkcdcAwL.pdf). Here’s what they say on page 8: “Important: If 5 cycles of reconditioning does not improve battery performance, discontinue and recycle the battery. The battery charger will go into charging mode after 24 hours automatically.”

I hope that helps answer your question!

Hi, Bought a 12v 98Ah deep cycle battery recently and pugged in my camping fridge, the fridge has auto cut off if there is not enough voltage. Ran it for a week and the error came up that the voltage was too low.

CHarged the battery for a few hours and it was all good. Next time the error came up pI checked the voltage, it was 11. Connected the charger and left it overnight, nor reads 12.2 and seems stuck there (although charger still says charging). Have I killed it? Or do I just keep on charging?

Hi Alex,

Based on the information provided, it does seem like the battery may have been over-discharged by the fridge. If the battery wasn’t fully charged to begin with, this could have contributed to the issue. Additionally, the charge after the first week of usage may not have been enough to fully recharge the battery.

Continued use of the battery after it was deeply discharged (less than 50% state of charge) can damage the battery plates. This could potentially be the reason why the battery is stuck at 12.2V despite charging overnight.

You may still be able to salvage the battery, but it may require more careful charging and monitoring to avoid further damage. If you have another charger, you may want to try using it to eliminate the possibility that the issue isn’t with the charger. Otherwise, if the battery still doesn’t hold a charge after attempting to recharge it, it may need to be replaced.

I hope that helps!

Comments are closed.